Cart (0)

14 dni na zwrot

Zawsze masz możliwość odstąpienia od umowy w terminie 14 dni bez podania przyczyny

Profesjonalne wsparcie

Oferujemy profesjonalne doradztwo naszych specjalistów przy doborze produktów

Gwarancja jakości

Dajemy gwarancję jakości na asortyment w naszym sklepie

Szybka wysyłka

W większości nasz towar jest dostępny na magazynie, co skraca czas wysyłki!

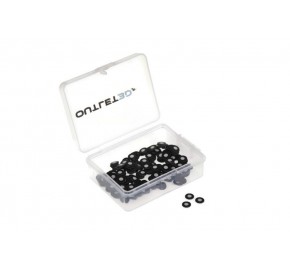

Magnetic reference points

Reference points necessary for 3D scanning

Whether or not you are scanning manually or with the use of a tripod, 3D scanning accessories cannot be missing reference points . Their task is to create a network of reference points for the laser scanner while creating a 3D model in a special computer program. Two types of meaning markers are most commonly used:

-

glued reference points,

-

magnetic reference points.

Magnetic reference pointsit is used both in industry and in the implementation of individual projects. All you need to do is select the size of the markers appropriate to the object. In this case, you can follow the rule - the larger the object, the larger the diameter of the points should beyle = "font-size: 11pt; font-family: Arial; color: # 000000; background-color: transparent; font-weight: bold; font-style: normal; font-variant: normal; text-decoration: none; vertical-align: baseline; white-space: pre-wrap; ">reference for 3D scanning. Thanks to the presence of markers, the scanner program remembers their arrangement, adds subsequent layers, and as a result creates a complete 3D model. It is important that the scanner can see at least three reference points simultaneously.

Magnetic reference points in Outlet3d.eu

Magnetic reference pointsare intended for laser scanners . For this reason, the color of the markers is important. The expressive bright or black color is easily recognized by the laser in the scanner. Magnetic reference pointsat Outlet3d.eu they can be used many times and are by far the most popular form of positioning metal objects. Let's summarize the most important advantages of magnetic reference points :

-

optimal visibility for the scanner,

-

canpossibility of more precise 3D scanning,

-

easier creation of a three-dimensional model in the program,

-

ease of installation on site and removal after scanning,

-

quick assembly on object,

-

reusable.