The scanner was used as a demo version

Description:

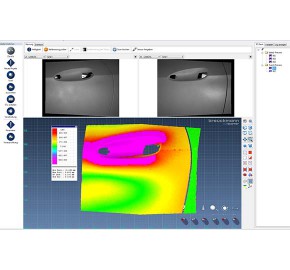

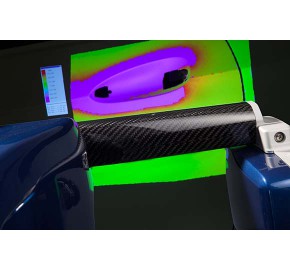

Deviations from the CAD model become visible on the surface of the scanned object Extraordinary precision and repeatability thanks to the rigid construction (double carbon fiber structure) The highest performance in inspection and reverse engineering is obtained both in the laboratory and in production conditions.

3D scanning with the highest precision Adaptive color projection with color and brightness controls Back-projection of measurement results (e.g. CAD comparison) Short scanning times thanks to digital projection Quick and easy exchange of measuring fields Highest precision thanks to high resolution cameras Can be combined with a contact probe Highest scanning stability Image processing

Control computer: Professional workstation Computer interface: GigE Operating system: Microsoft Windows 7 (64 Bit) System software: OPTOCAT for Windows From precise calibration, through data collection and to the final 3D model (with or without markers) Edge Detection software modules: includes Data interface: BRE, STL, PLY, VRML Cameras Camera resolution: 2 x 8 megapixels or 2 x 16 megapixels Minimum distance between points: 18 μm or 12 μm Smallest measuring field: 75 mm Largest measuring area: 1,100 mm Download time: minimum 1 second System weight: 12 kg Dimensions (W x D x H): 600mm x 430mm x 260mm Operating temperature in the range: 5 ° C to 45 ° C, non-condensing Power supply: AC 110/230 Volt, 50-60 Hz Accessories MoveInspect DPA MI.Probe mini Rotary table Swivel rotary table Tripod Computer station