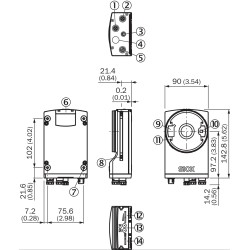

IMAGE-BASED CODE READER SICK V2D654R-MCXXA6 Lector64x/Lector65x

Device Specifications:

- Model: V2D654R-MCXXA6 – Lector 64x / Lector 65x Vision Barcode Reader

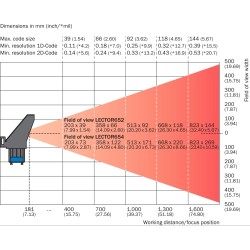

- Optical focus: Adjustable focus (manual)

- Sensor: CMOS matrix, grayscale values

- Sensor resolution: 2,048 x 2,048 pixels (4.2 megapixels)

- Illumination: To be ordered separately as an accessory

- Alignment aid: Red laser, 630 nm – 680 nm

- Laser class: Class 1, compliant with 21 CFR 1040.10 and 1040.11, except for conformance with IEC 60825-1 Ed.3., as described in “Laser Notice No. 56” dated May 8, 2019 (IEC 60825-1:2014, EN 60825-1:2014+A11:2021)

- Lens: C-mount

- Optical format: 1″

- Scanning frequency: 40 Hz at 4 megapixel resolution

- Code resolution: ≥ 0.1 mm

- Power supply: 24 VDC

- Model series: LECTOR 650

Supported Code Structures

- Readable code structures: 1D codes, stacked codes, 2D codes

- Bar code types: GS1-128 / EAN 128, UPC / GTIN / EAN, Interleaved 2 of 5, Pharmacode, GS1 DataBar, Code 39, Code 128, Codabar, Code 32, Code 93, USPS (Postnet, Planet, USPS4SCB), Australian Post, Dutch KIX Post, Royal Mail, Swedish Post

- 2D code types: Data Matrix ECC200, GS1 DataMatrix, MaxiCode, QR Code

- Stacked code types: PDF417

- Code qualification: Based on ISO/IEC 16022, ISO/IEC 15415, ISO/IEC 18004

- Internal image storage: 512 MB

Applications of SICK V2D654R-MCXXA6 / Lector 650

Industrial Automation and Logistics

- Product identification on production lines

- Component tracking during the assembly process

- Label verification and validation

- Monitoring of goods flow in warehouses (intralogistics)

Packaging and Food Industry

- Code reading on both individual and bulk packaging

- Batch verification and expiry date control (track & trace)

- Product identification in high humidity or dusty environments

Distribution and Courier Centers

- Parcel scanning on automatic sorters

- Reading codes from various angles and surfaces (thanks to image-based technology)

- High scanning speed (40 Hz) enables handling of high throughput

Automotive and Electronics

- Identification of parts and components on assembly lines

- Integration with MES (Manufacturing Execution Systems)

- Operation in harsh industrial environments (oil, vibration)