2682.93 tax excl.

Odstapienie od umowy w terminie do 14 dni bez podawania powodu

Przedmioty dostępne na magazynie wysyłamy w dni robocze w przeciągu 24 godzin

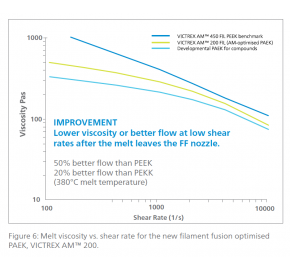

The new VICTREX AM™ 200 PAEK material has been developed for many demanding applications due to its very high abrasion resistance, heat resistance, fatigue resistance and corrosion resistance in contact with fluids/chemicals. Thanks to its features, the potential for design freedom and production cost efficiency has been increased. VICTREX AM™ 200 has much stronger interlayer bonds than PEEK filament due to its slower rate of crystallization. 3D printed parts with the VICTREX AM™ 200 have very low anisotropy, with Z-axis strength exceeding 60% of X/Y strength.

The material is also thermally stable with a melting point of 304°C and a slightly higher glass transition temperature of 156°C than PEEK.

Components printed with VICTREX AM™ 200 and subjected to an annealing process exhibit mechanical properties comparable to parts made of PEEK. The slow rate of crystallization of this material is also a factor in reducing warping, which translates into a higher achievable precision and level of detail in printed models. This is the solution for printing high-precision, high-strength parts that need to be extremely strong in all directions and work in high-temperature environments.

Weight: 500g

Color- Natural

Melting point: 303 °C

Tensile strength* 70 MPa

Tensile elongation* 15%

*in YZ orientation