The Devil Design PA12 filament is a versatile nylon material gaining popularity in the 3D printing world due to its exceptional properties. Nylon is easy to process, meaning PA12 prints can be further machined and polished, allowing for precise customization to meet specific requirements. One of the defining characteristics of this filament is its high hygroscopicity, meaning it absorbs moisture from the environment, so storing it in a dry place is recommended. PA12 is also highly impact-resistant, making it resilient to mechanical damage. Additionally, this filament offers strong resistance to greases, oils, fuels, hydraulic fluids, salt solutions, and solvents, making it ideal for industrial applications. PA12 can be used across a wide temperature range, which adds to its versatility. However, it is challenging to print with, so it is recommended for experienced 3D printer users who can adjust printing parameters to suit the material's specifics. Devil Design PA12 is the perfect choice for professional projects requiring both durability and precision.

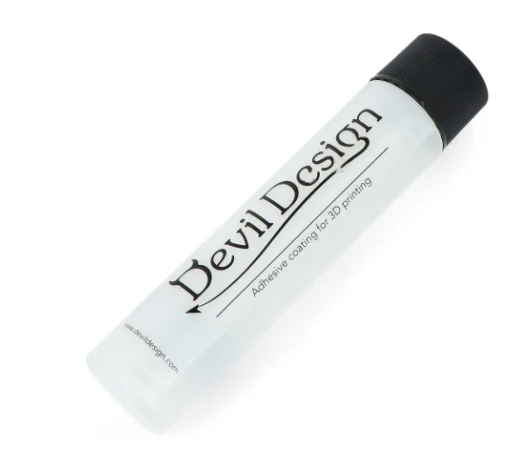

Due to its temperature requirements, nylon PA12 necessitates a high-quality, all-metal hot end capable of withstanding temperatures above 250°C. Additionally, this material has a tendency to warp, making strong adhesion to the build platform essential for optimal results. Nylon PA12 performs well with proper printer preparation—it is recommended to use an enclosed chamber and adhesive solutions (as shown in the photo) to minimize material shrinkage.

Viscosity number (m-cresol) DIN EN ISO 307 189ml/g

Water content ISO 15512 0,051%

Data sheet

Specific References